Manufacturing

The Dual Unit of Measure app allows you to output or consume items in weight/volume and units. The app also supports creating Production BOMs using Dual Unit of Measure items as components.

This documentation assumes you have a working knowledge of Manufacturing in Business Central. If you are new to Manufacturing, we recommend that you familiarise yourself with the standard Business Central documentation, which you can find here.

Production BOMs

We have added the Units Per on the Production BOM Lines, which you can specify for Dual Unit of Measure items. This field is used to specify the number of units of the item required for each item produced.

Business Central allows you to specify the unit of measure on your Production BOM. Depending on the nature of the product, it could make sense to define the Production BOM using the finished item's Units unit of measure code (e.g. pieces instead of weight). Refer to the scenarios below to view different approaches and how they affect the Production Order.

BOM Structure

The BOM Structure page has also been extended to show the units of components when applicable.

Production Orders

We have extended the production order pages (Simulated, Planned, Firm-Planned, Released and Finished) to support Dual Unit of Measure items.

Production Order

The following fields are added to the header:

| Field | Purpose |

|---|---|

| Unit of Measure - Units | Specifies Unit of Measure of the Units to produce. |

| Units | Specifies how many units to produce. If you enter a value here, the app will update the Quantity using the setup against the item. If you update the Quantity, the app updates this field, too. |

- You cannot specify units when the Source Type is Family or Sales Header.

- The app supports dual unit of measure items that are part of families or copied from a sales order. When you refresh the production order, the units will be copied to the Production Order lines.

Production Order Lines

The following fields are added to the lines:

| Field | Purpose |

|---|---|

| Unit of Measure - Units | Specifies the Unit of Measure of the Units to produce. |

| Units | Specifies how many units to produce. If you enter a value here, the app will update the Quantity using the setup against the item. If you update the Quantity, the app updates this field, too. |

Production Order Component Lines

The following fields are added to the component lines:

| Field | Purpose |

|---|---|

| Unit of Measure - Units | Specifies Unit of Measure of the Units to produce. |

| Units Per | Specifies how many units of the component are required to produce the parent item. If you enter a value here, the app will update the Quantity per using the setup against the item. If you update the Quantity per, the app updates this field, too. |

| Units per (Units UOM) | Specifies the units per based on the finished item's unit conversion. See additional info below. |

| Quantity per (Units UOM) | Specifies the quantity per based on the finished item's unit conversion. See additional info below. |

| Expected Units | Specifies the units of the component expected to be consumed during the production of the units on this line. |

Business Central usually defaults the Production Order unit of measure to the base unit of measure of the finished item. However, production BOMs are often defined based on the units unit of measure, which results in the Production BOM components reflecting the units per and quantity per that have been converted. The Units per (Units UOM) and Quantity per (Units UOM) always show the values based on the finished item's unit conversion - regardless of the Production Order unit of measure. You can update these values, and the app will automatically update the Units Per and Quantity Per fields.

Journals

We have added Units to the Production, Output and Consumption Journals. The journals will allow you to specify the units and weight/volume.

Scenarios

Scenario 1: Production BOM defined in Units

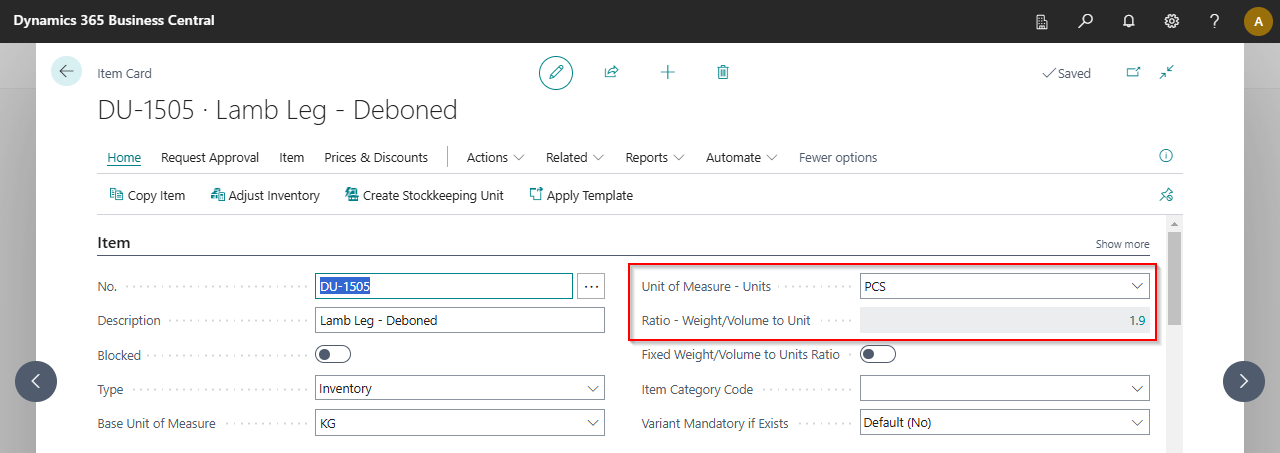

Item Card

Below is the item card for our finished item. You will notice:

- The item is a Dual Unit of Measure item.

- The Base Unit of Measure is KG.

- The Units Unit of Measure is PCS.

- The Ratio - Weight/Volume to Unit is set to 1.9, which means the average weight per piece is 1.9kg.

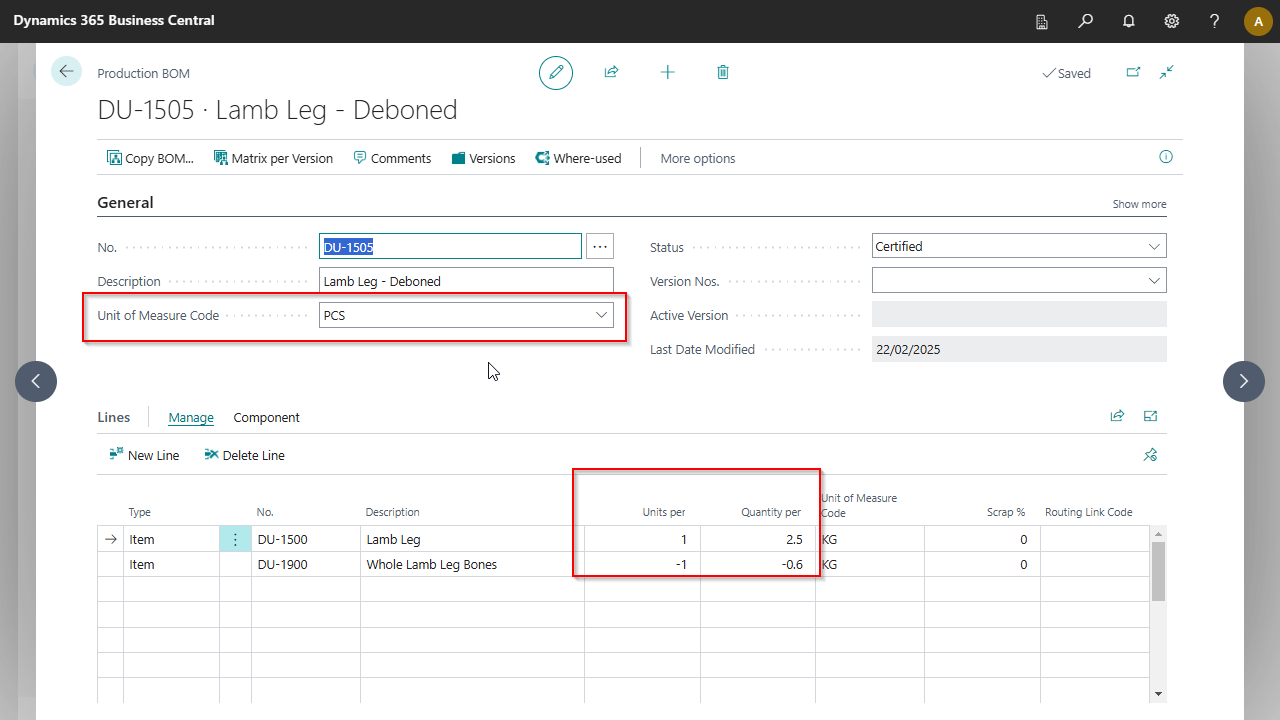

Production BOM

Below is the Production BOM for the finished item. You will notice:

- The Production BOM is defined in PCS.

- The first component (Lamb Leg) Units Per is set to 1 and the Quantity Per is 2.5.

- The second component (Whole Lamb Leg Bones) Units Per is set to -1, and the Quantity Per is -0.6. We have specified negative values because the bones are byproducts we will sell to pet food manufacturers.

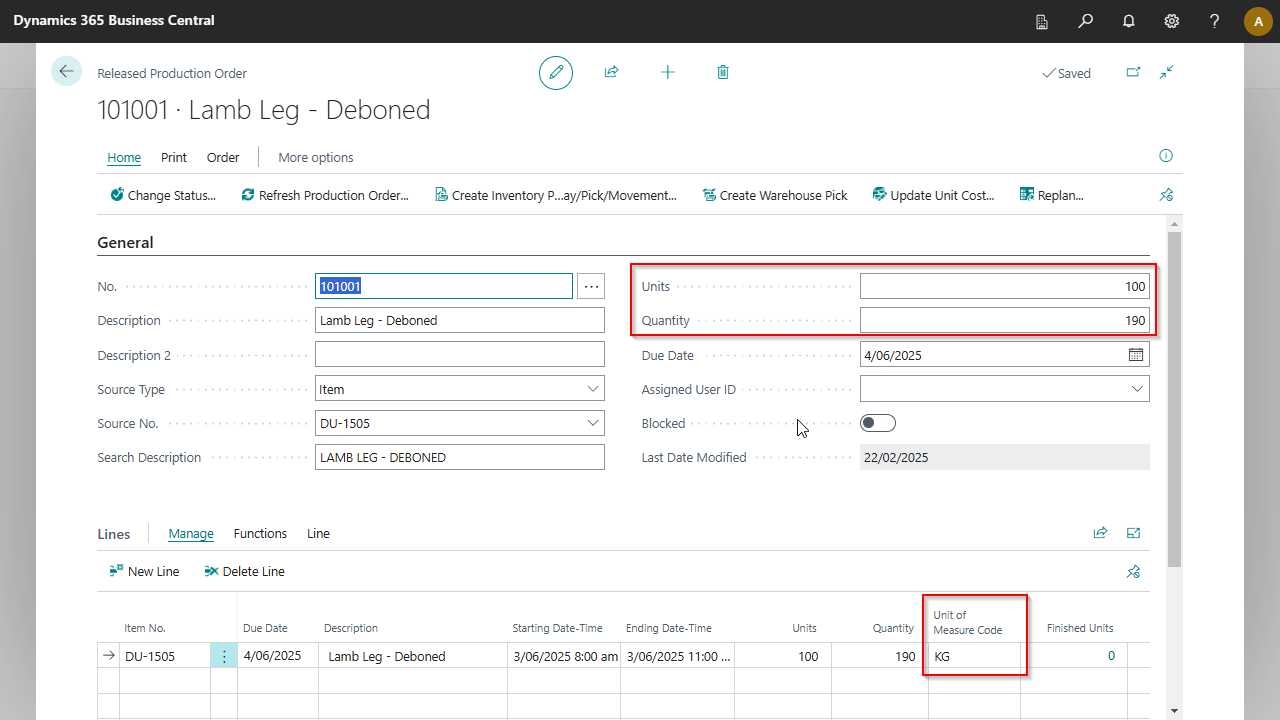

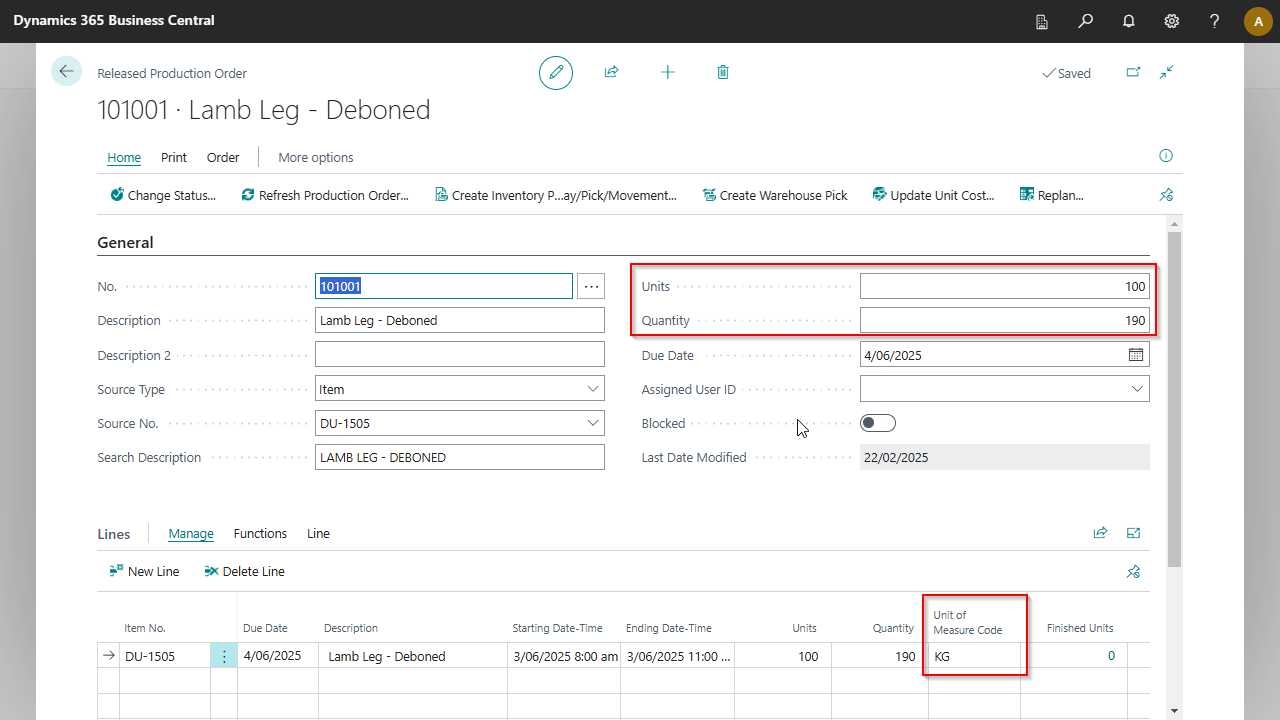

Production Order

Below is the Production Order for the finished item. You will notice:

- On the header: - The Units is set to 100, so we plan to produce 100 pieces. - The Quantity is set to 190, which means we plan to produce 190kg.

- On the line: - The Unit of Measure is set to KG. This was defaulted when we refreshed the production order.

_

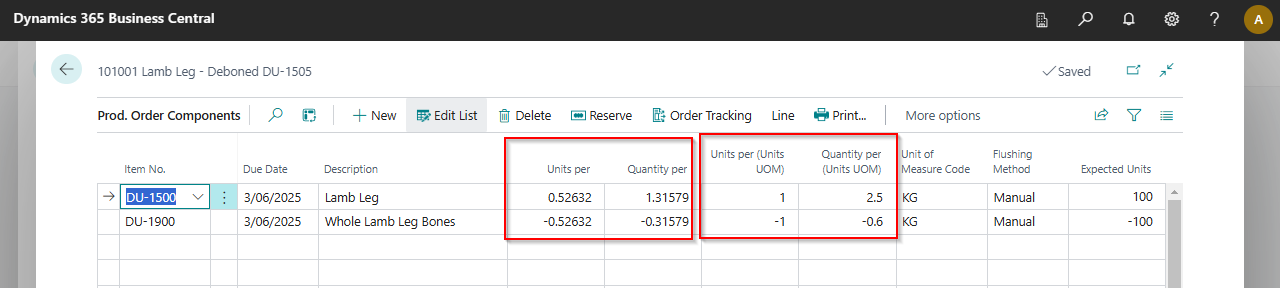

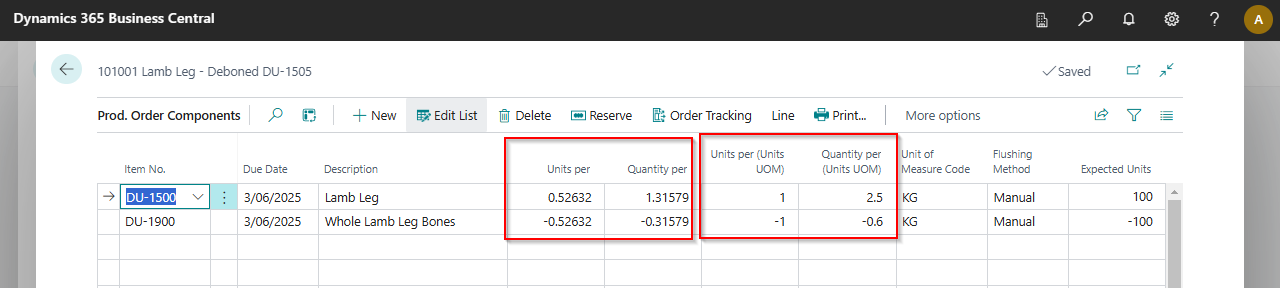

Component Lines

Below are the component lines for the Production Order. You will notice:

- Business Central converted the Units Per and Quantity Per when we refreshed the production order. This occurred because the Production Order's unit of measure is KG, and the Production BOM is defined in PCS.

- The Units Per (Units UOM) and Quantity Per (Units UOM) show the values based on the finished item's unit conversion. These values were copied directly from the Production BOM.

Scenario 2: Production BOM defined in the Base Quantity

This scenario uses the same items as Scenario 1, but the Production BOM is defined using the base quantity. We have decided to create a new version of the original production BOM rather than a different one.

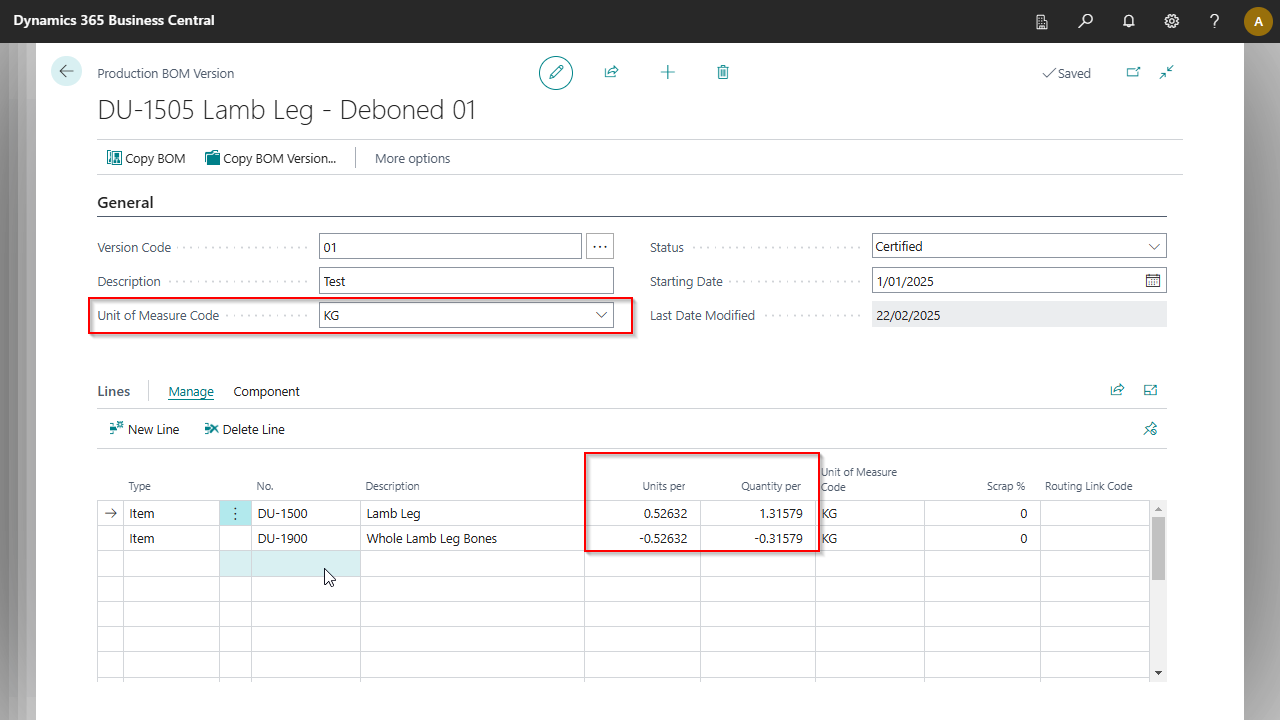

Production BOM

Below is the Production BOM for the finished item. You will notice:

- The Production BOM is defined in KG.

- The first component (Lamb Leg) Units Per is set to 0.52632 and the Quantity Per is 1.31579.

- The second component (Whole Lamb Leg Bones) Units Per is set to -0.52632 and the Quantity Per is -0.31579. We have specified negative values because the bones are byproducts we will sell to pet food manufacturers.

Production Order

We're using the same production order as the previous scenario 1. After certifying the new production BOM version, we have refreshed the production BOM. You will notice that the values are all as per scenario 1 above.

Component Lines

Even though the Production BOMs were defined with different units of measure, we still have the same result on the component lines. This is because the Production Order unit of measure was the same in both scenarios.